BDO-SERIES

(X/Y AXES LINEAR GUIDE WAYS,

Z AXIS BOX WAY) |

|

|

| VERTICAL MACHINING CENTER 》EXTRA HIGH SPEED BOX WAYS |

|

VMC-127H

VERTICAL MACHINING CENTER

Most Suitable for Needing High Speed, High Cutting Rate,

High Rigidity Mold Making Industry Most Suitable for Needing High Speed, High Cutting Rate,

High Rigidity Mold Making Industry

- X & Y axes has a hardened box-way design, Z Axis with SCHNEEBERGER roller-rail linear guide way, MRA45 rollers.

- Hollow ball-screw (Ø50-P16) with air cooling system for X-, Y-, and

Z- axis drive. Design with shock absorber

- Rapid traverse rate 30000 mm/min, cutting feedrate 1-12000 mm/

min.

- Design of C-type column with hydraulic weight-balance system

instead of using conventional chain-linked balance weight (To

prevent the unexpected vibration from fast z-axis drive)

- Direct connection using a coupling for Z-axis motor.

- Chip disposal system (3 screws and chip flush system

on two sides)

- Design of fully support for X and Y-axes to gain

the high stability and low vibration.

- Most suitable for needing high speed, high

cutting rate, high rigidity mold making industry.

Without the shortcomings of high heat, high

noise and high vibration when spindle speed

running more than 8000rpm.

Shorten the Distance Between Work Piece and Operator Shorten the Distance Between Work Piece and Operator

- An indented foot space allows operators to get closer to the table and workpiece.

- The location of the Y-axis servomotor is at the back of the machine to shorten the distance between the operator and table for greater work area access.

Safety Enhancement

& Modulus Integrated Design Safety Enhancement

& Modulus Integrated Design

|

|

|

|

Innovative Design Enhanced By

Scientific Analysis Innovative Design Enhanced By

Scientific Analysis

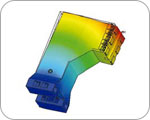

Finite Element Analysis is used to supplement traditional machine design by strengthening areas generally overlooked by designers.

|

|

Rigid Spindle Design Rigid Spindle Design- Heavy duty precision spindle bearings.

- A direct drive, 50-taper, 10,000RPM spindle headstock mounts to a linear guide way Z-axis slide, enabling a rapid traverse speed of 30 meters/min (1.180in/min).

|

|

Superior Structure Superior Structure

- C-Frame column with heavy duty roller-rail guide ways on the Z-axis.

- The VMC-127H uses an hydraulically activated nitrogen counterbalance system instead of conventional counter weights to help minimize vibration during rapid Z-axis movements.

|

|

Temperature Control System for Each Ball Screw Temperature Control System for Each Ball Screw

- All ball screws are air-cooled through the center to reduce thermal growth and enable better machine accuracy.

- X and Y axis have hardened way construction. The Z-axis uses roller-rail linear guide ways.

|

|

Ball-Bar Testing Ball-Bar Testing

Each machine goes through telescoping ballbar tests to check contouring accuracy and uncover any geometric errors. This testing ensures the machine structure is both square and parallel. |

|

Hand Scraping Hand Scraping

To ensure consistent high quality, each slide way is hand-scraped. Each axis saddle has Turcite material on it and a special “*" design is used along with a "Z" pattern for efficient oil troughs. There is an excellent distribution of oil to all axes, so setting time after rapid movements is eliminated, and stick-slip during cutting is minimized.

|

|

Calibration with Laser Interferometer is Performed and Certified by PMC Calibration with Laser Interferometer is Performed and Certified by PMC

All of our machines are calibrated according to the "VDI 3441 3∂" standard. Calibration is performed for full travel

length for each axis. Each measurement is taken six times to ensure the most consistent and accurate readings. |

|

Friction Coefficient Testing Friction Coefficient Testing

After the exclusive "*" pattern hand scraping, technicians inspect the results using torque measurements to make sure the ratio of contact region is over 50% and it is uniformly distributed. In addition, all contact points have a similar size, which helps maintain even static and dynamic resistance over the entire travel range of each axis. |

|

Simple Tool Length

Measurement (Option) Simple Tool Length

Measurement (Option)

Used mostly for drilling and tapping, the Metrol system T-27R probe only measures tool length. This simple cost effective system greatly reduced tool set-up time by automatically in putting tool length values once the probe touches the tool. |

|

Linear Scales for lmproved

Repeatability (Option) Linear Scales for lmproved

Repeatability (Option)

Linear scales on the X and Y-axes offer an exceptional positioning accuracy of up to 0.005mm over the full axes strokes. Only Heidenhain linear scales with a thermal behavior similar to that of the machine are selected so that thermal expansion can be compensated for further enhanced repeat-ability. Sealed encoders with durable aluminum housings offer improved reliability and service life. |

|  Coolant Through Spindle (C.T.S.)

(Option) Coolant Through Spindle (C.T.S.)

(Option)

Coolant through the spindle with pressure of 20-bar(150-psi) effectively reduces tool wear because of heat and the slow evacuation of metal chips.

- CTS with higher pressure is also available.

|

|

Forceful Cleaning Spray-Gun Option) Forceful Cleaning Spray-Gun Option)

Equipped on the right front side of base,this unit along with the assistance of a high pressure coolant and air mixture helps increase table cleaning speed. |

|

Hinged-Belt Chip Conveyor(Option) Hinged-Belt Chip Conveyor(Option)

This allows for rapid and efficient chip removal during machining in order to maintain a clean machine. |

|

Automatic Lubrication System Automatic Lubrication System

All AGMA machines use a pressurized central lubricating system. The PLC controlled system allows all three axes to be lubricated evenly to maintain accuracy and prolong machine life. |

|

There Chip Auger Design There Chip Auger Design

Instead of using a costly chip conveyor, the special three-chip auger system efficiently removes metal chips

produced during machining. |

|

Oil Circulating Cooling System for Spindle Oil Circulating Cooling System for Spindle

A high efficiency spindle cooling system dissipates running induced heat generation in order to mainainspindle

accuracy and prolong spindle life. |

|

Electrical Cabinet Electrical Cabinet

All electrical components are in compliance with all safety rules and regulations. All components inside the cabinets are clearly labeled and identified for ease of troubleshooting. |

|

Pressurized Oil Distributor Pressurized Oil Distributor

Lubricating oil is evenly distributed to the sliding surfaces of the machine by using Showa brand oil distributors along with hard-plumbed,low maintenance oil lines. |

|

24 Tools Magazine 24 Tools Magazine

A rapid arm-type tool changer is driven with a precision cam, maintaining tool-changing accuracy of 0.01mm, which in turn will help maintain long-term spindle-clamping accuracy. |

|

|

|