|

A-14 All three axes adopt high precision 45mm roller-rail linear guideways and Ø45mm ball screws. A12/A14's unique four roller-rail linear guide ways with eight sliders on the Y axis enable the ultimate support for high speed and machining accuracy. With Meehanite cast iron across the mach ine structure, machine column and saddle are carefully designed with dual layers casting for the most rigid structure to absorb cutting vibration.

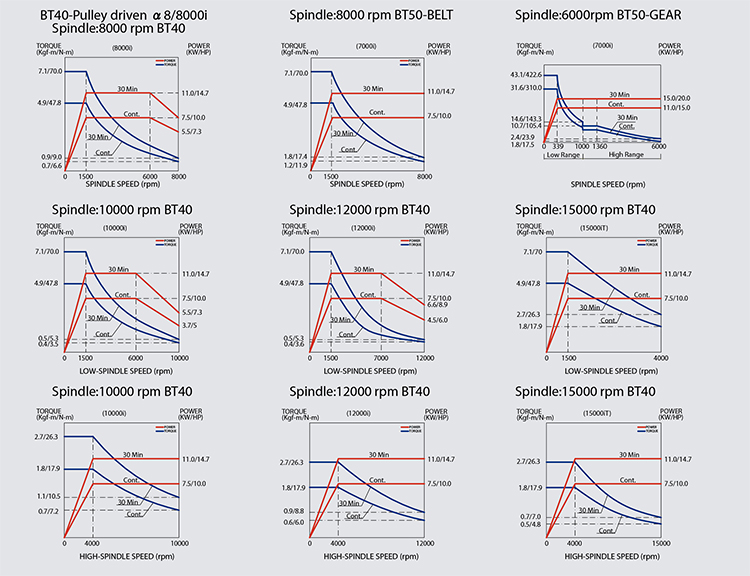

7kw (no counter balance design) for BT40. Ø45mm Pitch 12 C3 ball screw with high class double nut provides strong rigidity, high torque, better accuracy, longlife, and effectively heat extension control. The gas storage barrel assists to acquire steady air source to increase equipment utility rate. |

|

|

X & Z axes adopt 45mm width roller-rail linear guide ways including 2 tracks, and each track has 3 sliders (total 6 sliders) Y axis adopts 45mm width roller-rail linear guide ways, 4 tracks, each track with 2 sliders (total 8 sliders) |

|

screw-type chip augers on Y axis to increase the chip removable capacity. |

|

|

|

The unique column design achieves the ultra-excellent rigidity to minimize cutting induced vibration and deformation. |

|

Agma conduct 100% inspection to full travel length of three axes. Standard VDI 3441 3δis employed to ensure the machine accuracy and righteous of the inspection. For each axis, inspection along full axial travel length backwards and forwards for 6 times is conducted. |

|

|

|

|