VMC-95/115/116

|

|

This allows for rapid and efficient chip removal during machining in order to maintain a clean machine. |

|

A high efficiency spindle cooling system dissipates running induced heat generation in order to maintain spindle accuracy and prolong spindle life. |

|

THE C.T.S. (COOLANT THROUGH SPINDLE) (A TYPE) system provides 20 bar (280 PSI) of hi-pressure coolant delivery that effectively reduces tool wear because of heat and the slow evacuation of metal chips. |

|

All of our machines are calibrated according to the "VDI 3441 3δ" standard. Calibration is performed for the full travel length of each axis. Each measurement is taken six times to ensure the most consistent and accurate readings. |

|

The base of the VMC-95/116 has 4-hardened ways that allow for greater stability and accuracy even with heavy loading. In essence, the design fully supports the saddle and table along the entire travel lengths of the X and Y-axes. |

|

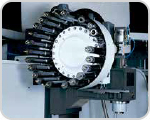

A rapid arm-type tool changer is driven with a precision cam, maintaining toolchanging accuracy of 0.01mm, which in turn will help maintain long-term spindle-clamping accuracy. |

|

All AGMA machines use a pressurized central lubricating system. The PLC controlled system allows all three axes to be lubricated evenly to maintain accuracy and prolong machine life. |

|

To prevent any deviation between the servomotor housing and ball screw bearing housing, each axis is equipped with two stoppers to guarantee absolute axial alignment. |

|

Lubricating oil is evenly distributed to all the sliding surfaces of the machine via volumetric oil distributors. All stationary lines are made of rigid alloy pipe and hard-plumbed for low maintenance operation over the life of the machine. |

|

Equipped on the right front side of base this unit along with the assistance of a high-pressure coolant and air mixture helps increase table cleaning speed. |